Replace a seal, save a $1 million dollar project

PREVENTIVE MAINTENANCE

Replace a seal, save a $1 million project

By Matt Defosse

Good things come in small packages, with a good example to be found at additive supplier Amfine. Running into serious problems with a dryer used to prepare nucleating agents, the company was able to replace a seal on a vacuum dryer and save a $1 million project.

Seals and other replacement parts often do not get much thought from the plastics community until it's rime to refurbish or conduct scheduled maintenance on a piece of equipment. There are times, though, when a bad seal can bring an entire project to a halt, as additives and PVC stabilizer supplier Amfine Chemical Corp. (Hopkinsville, KY) discovered when it was ramping up a line to produce a nucleating agent that also serves as a clarifying agent for semicrystalline polymers.

As they ran the first batches of product in the new dryer and tested the results for solvent content and dissolved color numbers, Amfine's experts realized that they needed to achieve a much deeper vacuum in order to reach the target values for solvent and color: A value of 50 Torr or less was needed in order to dry at a low-enough temperature to hit their targets. After making several changes to the configuration of the original seals, operators reported getting closer to the 50-Torr level in the dryer, but the product still did not meet QC standards.

The level of vacuum achieved with the factory-installed seals was inconsistent from batch to batch, so cycle times for the dryer ranged widely.

Nitrogen purge gas entering the dryer from the factory-supplied seals was making it impossible to achieve the 50-Torr level. The addition of nitrogen to the process had a secondary effect, to decrease the bulk density of the product, making it fluffier. The result of this was that fine particles began to clog the outlet filters, increasing the pressure differential between the inside and outside of the dryer, a potentially dangerous condition.

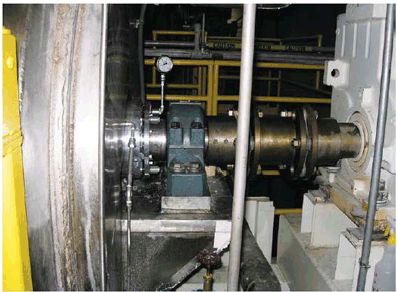

Mastering Murphy

After some searching, Amfine's facilities manager, Scott McNair, contacted shaft seal manufacturer MECO's regional distributor, Jerry Chevalier of Mid South Mechanical Sealing in Tennessee. After visiting Amfine, where he helped the maintenance team to measure the dryer shaft and the space around it for a custom seal, MECO (Georgetown, ME) quoted a split, elastomer-free ExPac (EP) model seal with a mechanical drive mechanism. These seals can accommodate axial shaft growth in applications with wide temperature and pressure variances such as this one had, and can hold vacuum effectively. The elastomeric drive version of the ExPac was ruled out due to the high temperature and chemical compatibility considerations in the application. The split design was critical because the retrofit of the dryer would take much less time if the bearing and drive could be left intact. The seal was delivered and installed in late April 2008. Chevalier helped with installation of the seal and to oversee the startup of the machine with the new seal in place. A seal sleeve slightly wider than the shaft diameter was removed to maximize available space for the new seal. The EP seal required a nitrogen purge, but with a significantly reduced flow rate compared to the first seal (from several hundred to near zero cfm).

Happy and profitable ending

When the seal was installed, plant operators were hoping that the dryer could pull a vacuum deeper than 50 Torr. In fact, it is able to consistently approach zero Torr with the new seal. Dryer cycle times became predictable, and consistent achievement of deep vacuum resulted in more consistent product quality and higher profitability for Amfine. The ExPac seal is designed for its seal face pressure to be adjusted occasionally as rotating faces wear over time. In the first 2 1/2 years of operation, the seals have not needed to be adjusted yet. McNair goes so far as to say that the seals "literally saved a $1 million project."