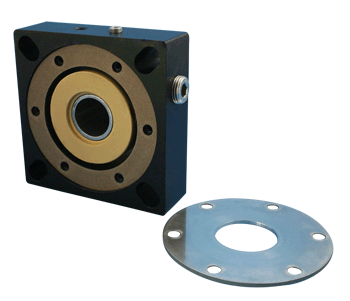

HC SEAL

Air Free Sealing Technology

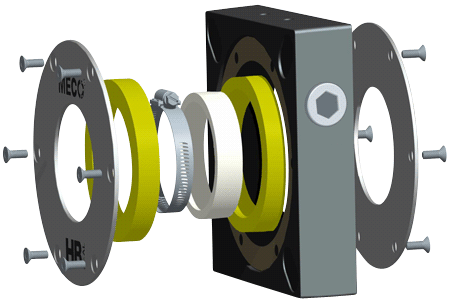

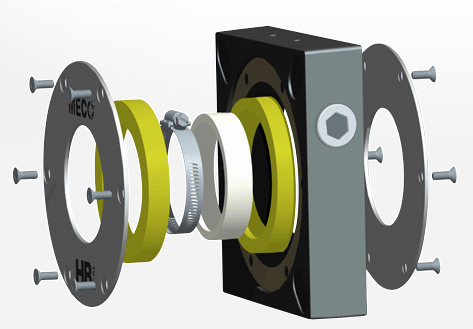

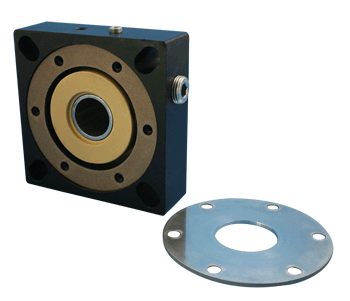

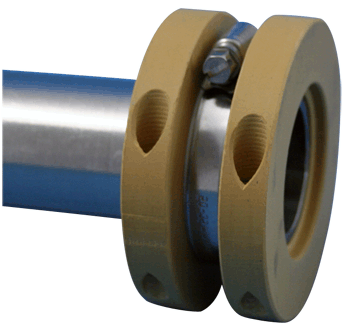

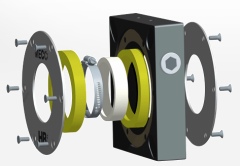

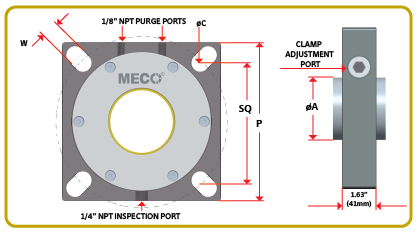

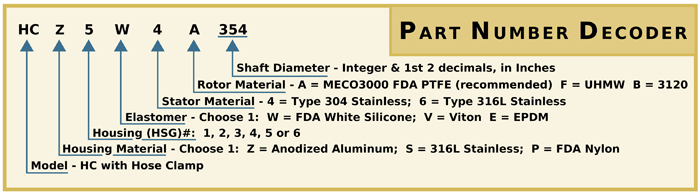

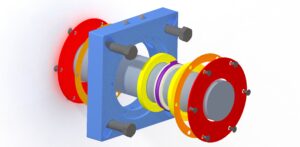

The MECO HC seal model is the best air-free choice in sealing technology for screw conveyors. The HC model is a full-contact, soft-face mechanical shaft seal, using an elastomer drive to rotate bearing-grade, polymeric seal faces against fixed, stainless steel seal faces. The various seal assemblies are sized for equipment following standards of the Conveyor Equipment Manufacturers Association (C.E.M.A.) and their metric equivalents

What is MECO’s HC Seal Model?

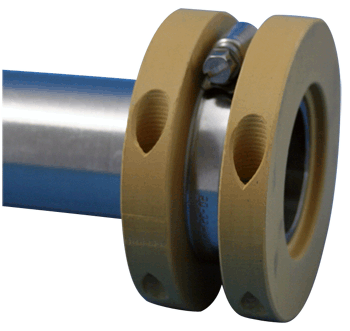

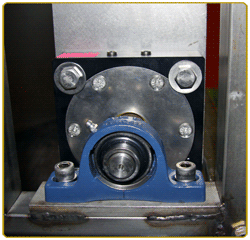

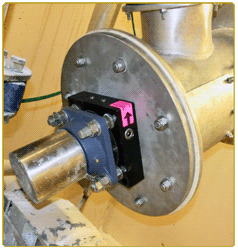

The MECO HC seal model is the best air-free choice in sealing technology for screw conveyors . The HC model is a full-contact, soft-face mechanical shaft seal, using an elastomer drive to rotate bearing-grade, polymeric seal faces against fixed, stainless steel seal faces. The various seal assemblies are sized for equipment following standards of the Conveyor Equipment Manufacturers Association (C.E.M.A.) and their metric equivalents.

The HC Seal model provides the superior performance, durability and quality of workmanship that are hallmarks of MECO’s many other highly-regarded custom seals. MECO’s first-rate customer service is provided for each HC seal sold.

When are HC Seals the Best Option?

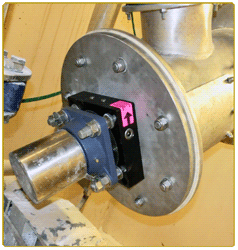

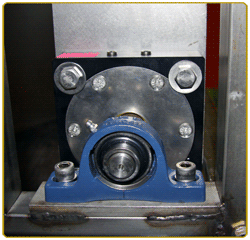

The MECO HC Seal model is ideal for screw conveyors/scrolls, small blenders, bucket elevators, and similar rotating equipment used in bulk process industries. The HC Seal model is used on horizontal, inclined and vertical shafts for unsplit installations