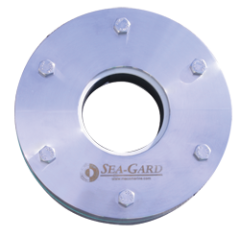

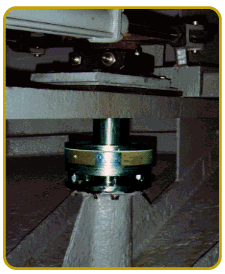

MECO Marine Sea Gard

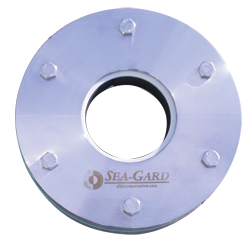

Rudder Post Seal

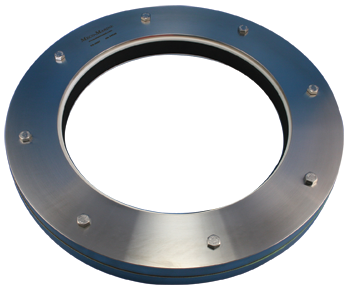

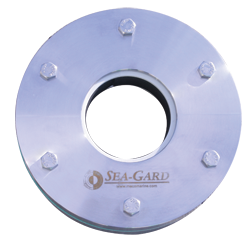

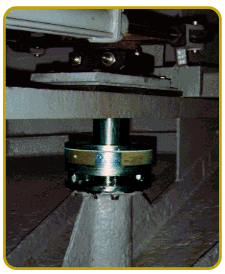

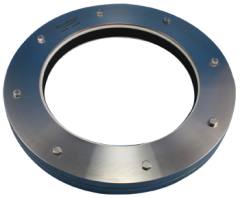

The SEA-GARD provides an effective rudder post seal in abrasive, coastal waters. Wear materials are softer than those used in traditional mechanical seals, and permit the use of wide-radius seal faces. These easily tolerate severe eccentric rotation and permit wear to occur without compromising the seal.

The SEA-GARD provides an effective rudder post seal in abrasive, coastal waters. Wear materials are softer than those used in traditional mechanical seals, and permit the use of wide-radius seal faces. These easily tolerate severe eccentric rotation and permit wear to occur without compromising the seal.

- • Elastomeric Drive Design Tolerates Shock Loads & Radial Eccentricity

- • Will Not Open Up Like Packing

- • Long Service Life

- • Fully-Split Designs Facilitate Easy Installation & Rebuild

The wide seal face radius permits the Sea-Gard to function despite severe bearing wear which causes other seals to leak. Seal face loading is accomplished by an elastomeric drive: there are no metallic springs to corrode and fail. The soft elastomer buffers shock loads and maintains seal integrity under the roughest operational conditions. The fully-split Sea-Gard is user-friendly and simple to install. Seal faces can be freely handled. There are no gauge blocks, calibration rods or special shaft finishes required for installation. An accurate shaft measurement prior to purchase ensures proper calibration on assembly. Sea-Gard seals are available in sizes to fit every rudder post diameter, and various materials permit compact designs for installation in areas with minimal axial clearance.