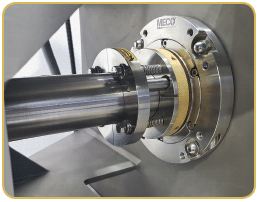

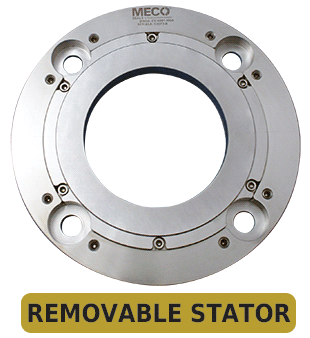

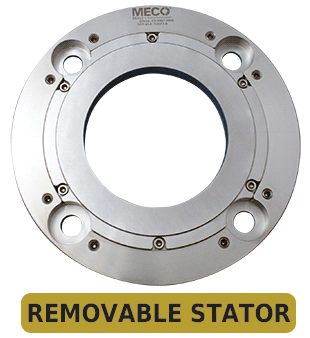

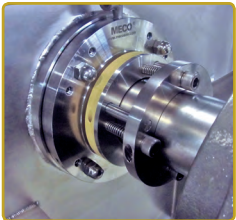

OFS Type-2

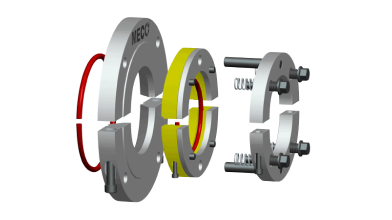

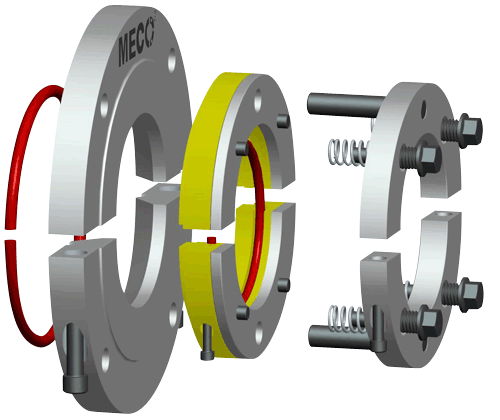

Full Contact, Soft Face Mechanical Seal

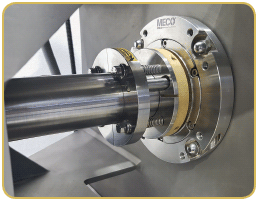

The patented MECO OFS Type-2 model is the best choice in many sealing applications for low to moderate speed equipment. The OFS Type-2 uses full-contact, soft-face mechanical shaft sealing technology, sized for OEM and custom in-house process equipment.

What Is MECO’s OFS Type-2 Seal?

The patented MECO OFS Type-2 model is the best choice in many sealing applications for low to moderate speed equipment. The OFS Type-2 uses full-contact, soft-face mechanical shaft sealing technology, sized for OEM and custom in-house process equipment. The OFS Type-2 model provides the superior performance, durability and quality of workmanship that are hallmarks of MECO’s many other highly-regarded seals. MECO’s first rate customer service is provided for each OFS Type-2 seal sold.

When Are OFS Type-2 Seals The Best Option?

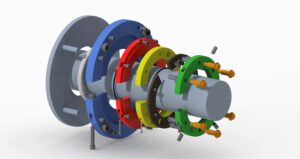

The OFS Type-2 seal model is ideal for blenders, mixers, cookers, conveyors and similar rotating equipment used in the food, pharmaceutical, chemical, plastics, metals, and other bulk process industries. The OFS Type-2 seal model is used on horizontal, inclined, and top entering shafts for split and unsplit installations. They are frequently used in dry powder blending applications including sugar drink mixes, spices, flavorings, nutrients, plastic and metal powders, and chemicals. It is also used in wet mixing for products like soups, sauces & pet foods.

The single-face OFS Type 2 seal is an air-free design, this allows users to steer clear of the costs and hassles associated with compressed air. The seal is extremely effective in vacuum service.

The OFS Type-2 seal model allows for easy, speedy cleaning. The seal may be washed in 10 minutes time while assembled on the blender or freely disassembled along the shaft for cleaning and inspection.