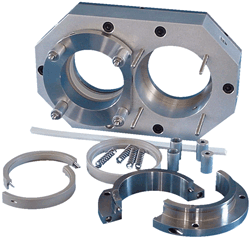

EP Type-2

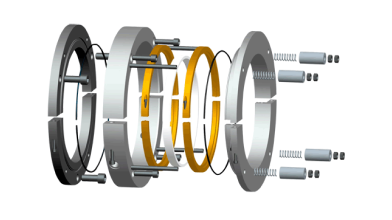

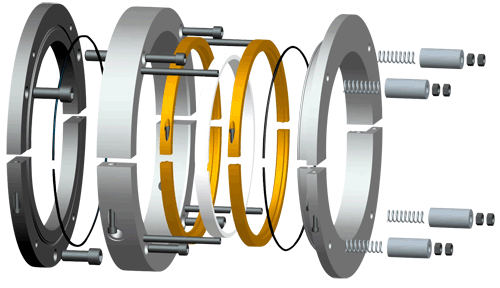

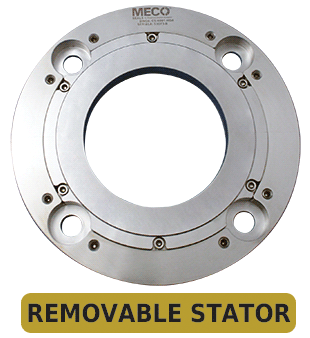

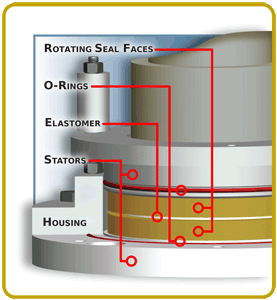

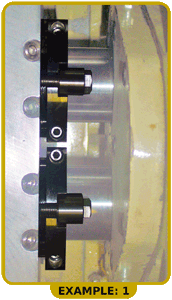

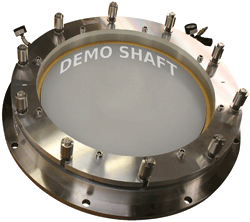

Double Mechanical Seal With an Elastomer Drive

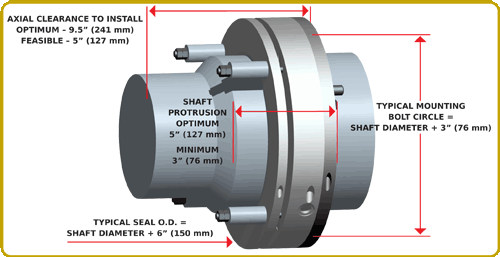

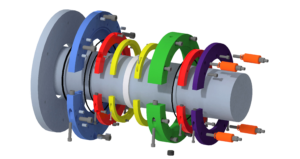

The MECO EP Type-2 model is the best choice for many sealing applications with low to medium-high shaft speeds, on small to large shaft diameters. The configuration is a double mechanical seal using an elastomer drive to rotate bearing-grade, synthetic seal faces against fixed, hardened stainless steel seal faces. The EP Type-2 uses full-contact, soft-face mechanical shaft sealing technology, sized for OEM and existing in-house process equipment. The EP Type-2 model provides the superior performance, durability and quality of workmanship that are hallmarks of MECO’s many other highly-regarded seals. MECO’s first-rate customer service is provided for each EP Type-2 seal sold.

What is MECO’s EP Type-2 Seal?

The MECO EP Type-2 model is the best choice for many sealing applications with low to medium-high shaft speeds, on small to large shaft diameters. The configuration is a double mechanical seal using an elastomer drive to rotate bearing-grade, synthetic seal faces against fixed, hardened stainless steel seal faces. The EP Type-2 uses full-contact, soft-face mechanical shaft sealing technology, sized for OEM and existing in-house process equipment. The EP Type-2 model provides the superior performance, durability and quality of workmanship that are hallmarks of MECO’s many other highly-regarded seals. MECO’s first-rate customer service is provided for each EP Type-2 seal sold.

When are EP Type-2 Seals the Best Option?

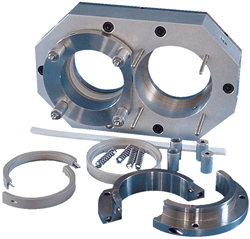

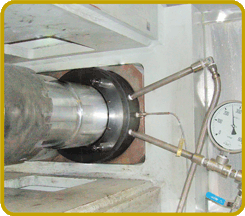

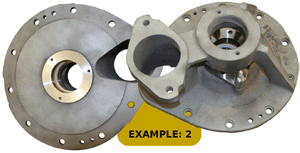

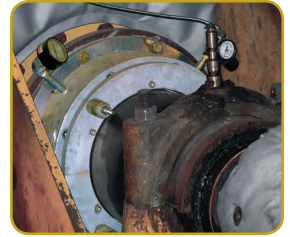

The MECO EP Type-2 seal is ideal for single- or twin-shafted extruder-compounders, plow blenders, paddle blenders, conveyors and similar rotating equipment used in the plastics, chemical, metals, pharmaceutical, food and other process industries. The EP Type-2 seal model is typically used on horizontal or inclined shafts configured for a fully-split installation. They are frequently used on polymer extruders containing particulates and vapors. They are well-suited for hard-to-access equipment and machinery with set speeds and feed rates. The seal is appropriate for vacuum service, low pressures and steady-state applications that experience infrequent thermal expansion or pressure changes. In contrast, the MECO Model EP Type-3 seal is better matched for the challenges of applications with frequent thermal cycles, pressure cycles and/or aggressive chemicals.