Seals for ATEX Applications

Explosive Atmosphere Applications

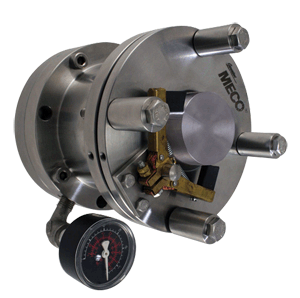

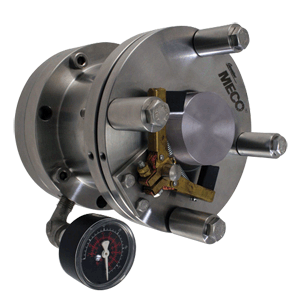

MECO Seals for ATEX Applications

ATEX is a series of explosion prevention standards, codified in EN 94/9/EC, to which equipment manufacturers must conform, in order to place machinery in service in Europe in potentially explosive environments.

What's ATEX all about?

ATEX is a series of explosion prevention standards, codified in EN 94/9/EC, to which equipment manufacturers must conform, in order to place machinery in service in Europe in potentially explosive environments. Compliance involves formal risk assessments and the use of certified machinery and components. ATEX was mandated in 2003, after which time new machinery must be compliant. Upgrades or retrofits to machinery which was in service prior to 2004 must also be ATEX-compliant.

Does MECO offer ATEX seals?

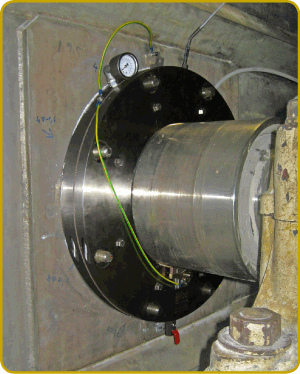

Yes - MECO seals can be designed for certain explosive atmosphere applications where EN 94/9/EC must be adhered to. For retrofit applications, where a new seal will be mounted on an older piece of machinery placed into service prior to adoption of 94/9/EC, MECO offers seals specifically EX-marked for ATEX service. For new machinery, equipment manufacturers can opt to purchase EX-marked and tested seals, or they may equip their new machines with a variety of unmarked MECO models, and then include the seals under the umbrella of their ATEX declaration for the completed machine.

How are MECO's ATEX seals different from other shaft seals?

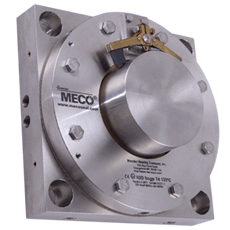

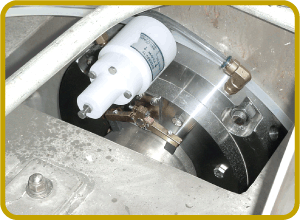

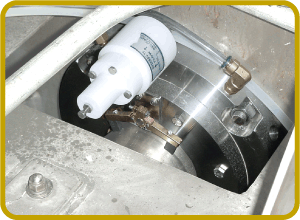

The use of packing glands and other high-friction seals in ATEX service can create an uncontrolled heat source and many European processors require alternative seals which are ATEX-compliant. Some mechanical seals advertise ATEX compliance, but require a liquid barrier for cooling, which is usually unacceptable in dry bulk processing applications. MECO's soft-face technology uses materials with high inherent lubricity, which run cooler than radial, constricting seals without the use of fluid lubricants.

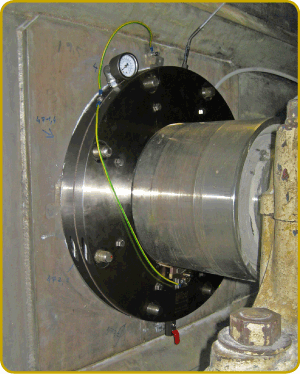

Several MECO seal models are available with ATEX certification. Common to all are a risk assessment, thermal testing and documentation, combined with a variety of protective measures designed to eliminate ignition sources, control surface temperatures and isolate process from atmosphere.

Before leaving the factory, every EX-marked MECO seal is run-tested under simulated process conditions to document surface temperature in operation and ensure that run temperature falls within the required temperature class and safety margin. A thermal test certificate is furnished with each seal.

What ATEX applications can MECO address?

MECO can design seals for Equipment Group II, Categories 2 and 3 D and G (Zone 1/21 or 2/22), where process parameters will permit the seal to operate within prescribed temperature and pressure limits. These limits vary considerably according to machinery and process requirements, so each ATEX seal is individually designed, built and marked for a specific process. MECO does not manufacture seals for Category 1 (Zone 0/20) service.