AH Type-2

Eliminate Setting Seal Face Pressures

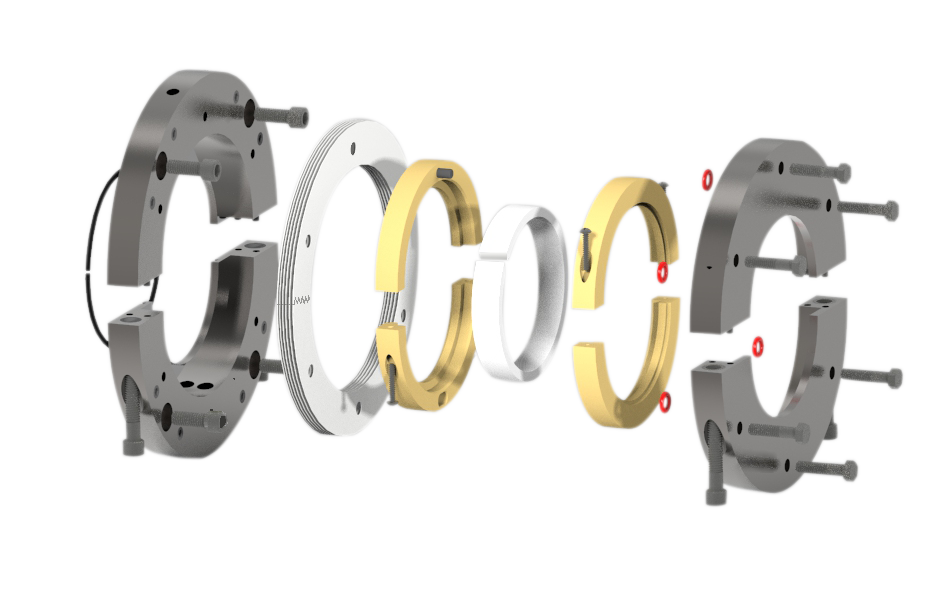

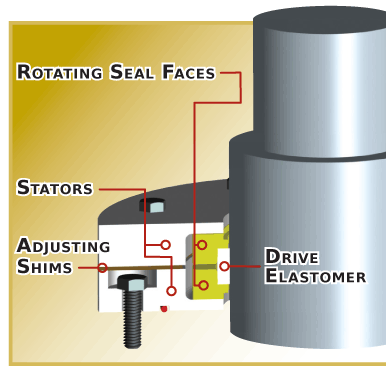

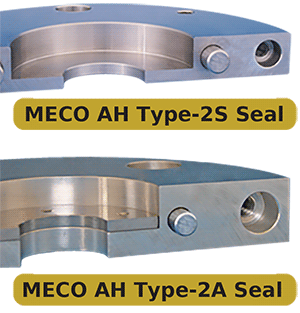

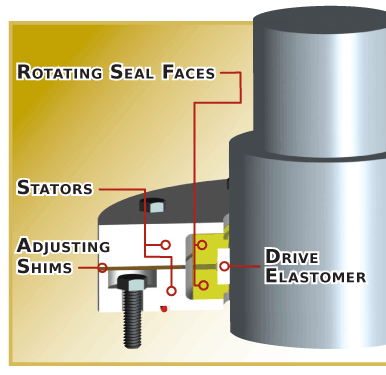

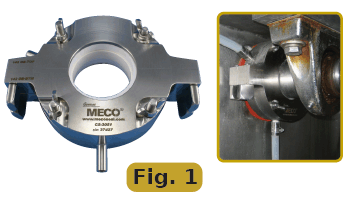

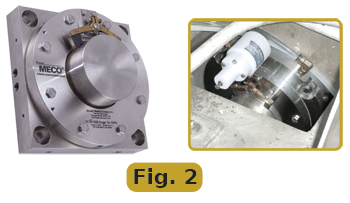

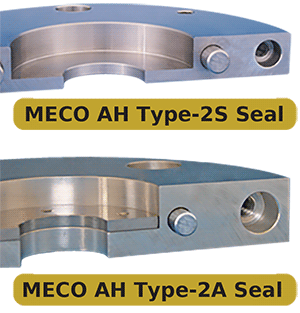

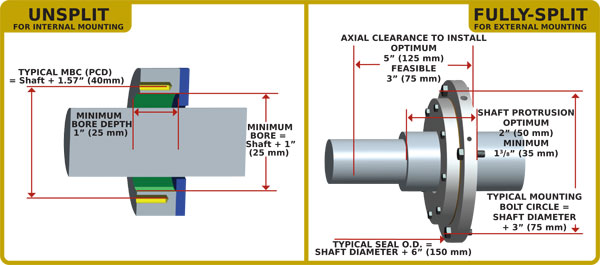

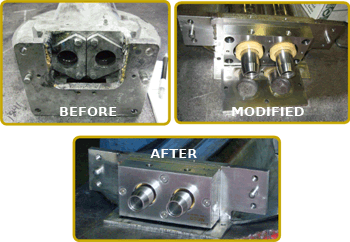

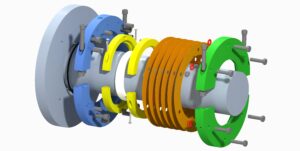

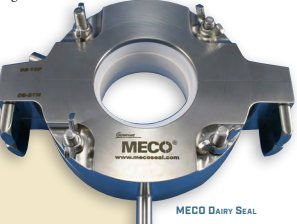

The MECO AH Type-2 model is a split seal, designed to fit in limited space on small to large shaft diameters. The configuration is a soft-face, double mechanical seal using an elastomer drive to rotate bearing-grade synthetic seal faces against fixed, stainless steel seal faces. The AH Type-2 uses a barrier gas to pneumatically load the seal faces and isolate the process from the atmosphere. The AH Type-2 is custom-designed to fit your equipment with minimal or no modifications.

What Is MECO’s AH Seal?

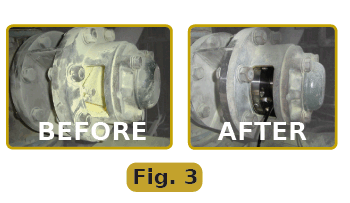

The MECO AH Type-2 seal is a fully-custom, pneumatically loaded shaft seal that can fit in limited axial space. In most cases, split components can be used, which makes replacing parts easy and minimizes maintenance downtime.

The AH Type-2 features a stack of adjusting gaskets that allows for field adjustments. It uses an elastomer to drive two polymer rotary seal faces (rotors). The rotors are kept in full contact with two stainless steel stationary seal faces (stators) by the elastomer and a compressed gas purge. The AH Type-2 seal can be designed to fit most shaft sizes.

Where Are AH Seals Used?

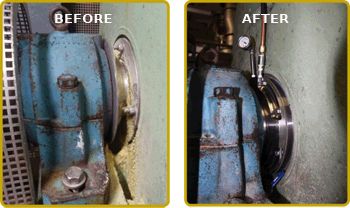

The MECO AH Type-2 seal model is used on a wide variety of conveying and process machines, often with limited axial clearance. This seal model can be used on horizontal, inclined, and vertical shafts. This seal is appropriate for applications with infrequent thermal expansion or pressure changes. It can be adjusted to extend the life of the seal. The AH Type-2 is frequently used where an air or an inert gas barrier is needed to isolate the process from the atmosphere. It can also be designed for explosive environments.

AH Type-2 seals are used on a variety of machines:

- Screw conveyors

- Blenders

- Bucket elevators

- Mixers

AH Type-2 seals are best suited in the following applications:

- Dry bulk conveying

- Dry chemical processing

- Plastic powder blending and colorizing

- Dry food conveying

- Dry and wet food mixing and cooking

- Explosive environments

The AH Type-2 seal is one member of MECO’s wide range of sealing solutions. Other MECO models may be considered for faster speeds, higher pressures, and thermal cycling. MECO evaluates the parameters of each application individually and provides a custom engineered solution. Contact MECO for a design to suit your specific application.

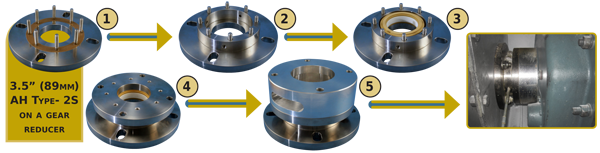

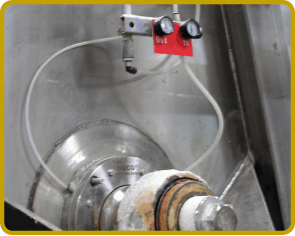

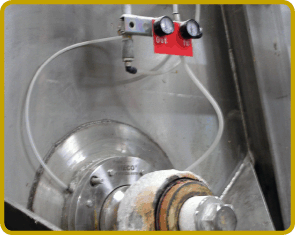

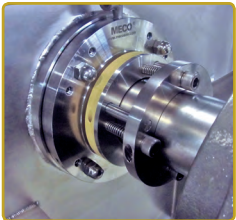

This seal can be designed to fit between the gear reducer and trough end of a screw conveyor, as shown below.