EA-Type1

Calibration Without Disassembly

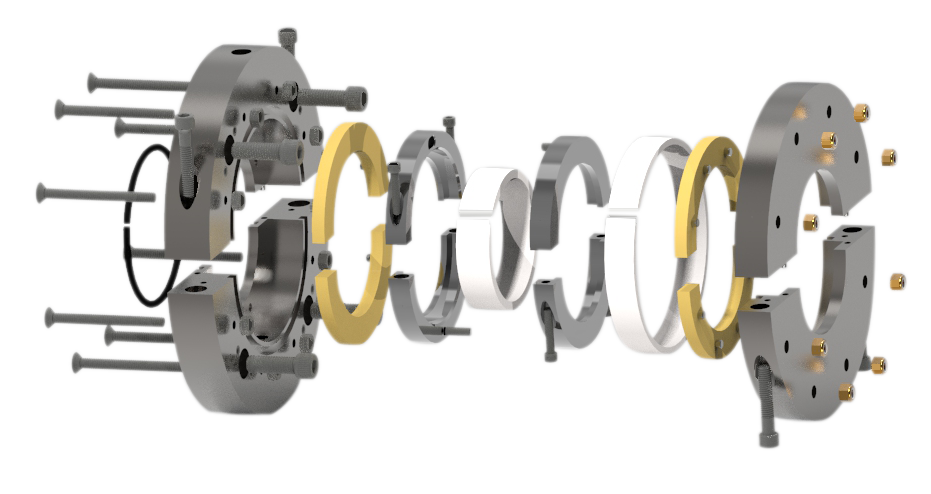

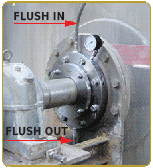

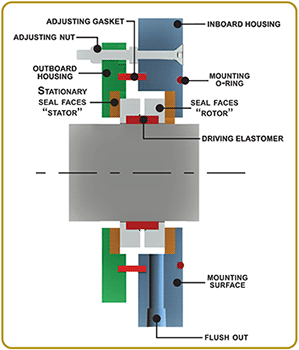

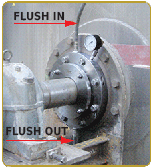

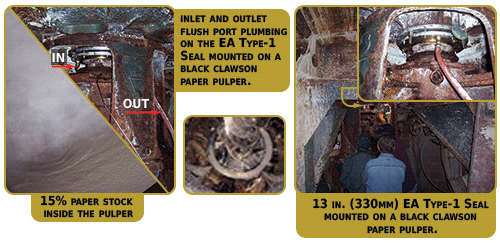

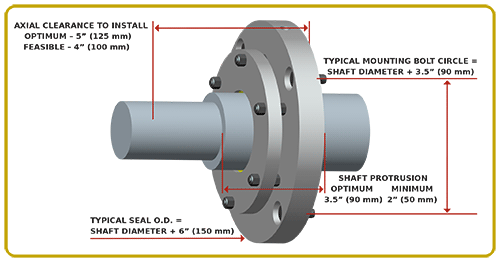

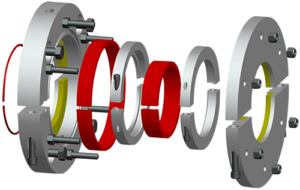

The MECO EA Type-1 fully-split seal model is a great selection when sealing wet slurries. The fully-split configuration uses an elastomer drive to rotate two, hardened stainless steel seal faces against two fixed, bearing-grade polymeric stationary seal faces with their contacting sealing plane set perpendicular to the shaft. The polymeric stationary seal faces are built into two fully-split stainless steel plates. One split plate is mounted to the vessel wall and the other is manually positioned a set distance from the mounted plate. Between the plates an elastomer is used to form a seal cavity where gravity-fed water flushes and cools the chamber with no back pressure applied.

What Is MECO’s EA Type-1 Seal Model?

The MECO EA Type-1 fully-split seal model is designed for sealing wet slurries. The fully-split configuration uses an elastomer drive to rotate two stainless steel seal faces against two fixed, bearing-grade polymer stationary seal faces with their contacting sealing plane set perpendicular to the shaft. The polymer stationary seal faces are built into two fully-split stainless steel plates. One split plate is mounted to the vessel wall and the other is manually positioned a set distance from the mounted plate. Between the plates an elastomer is used to form a seal cavity where gravity-fed water flushes and cools the chamber without any back pressure applied.

Where Are EA Type-1 Seals Typically Used?

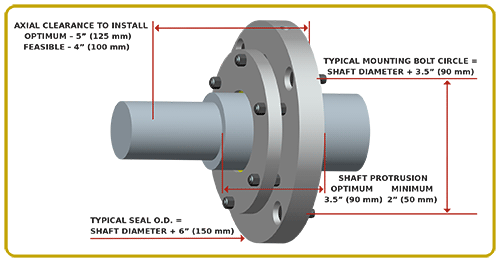

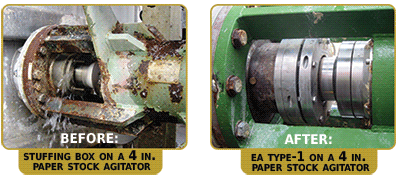

Where axial or linear space is limited, the MECO EA Type-1 seal model is the solution for sealing wet abrasive slurries encountered in pulpers, agitators, cylindrical blenders, paddle mixers, holding vessels, flocculators, mixing conveyors and similar rotating equipment. When linear space is available, MECO's EP Type-1 model should be considered. The EA Type-1 model is used in process industries such as pulp & paper, home building products, sewage and water treatment, biomass and ethanol production, along with other processes handling water slurries. They are frequently used on side-entry mixers containing drywall or sheetrock mud. They withstand the abuse of shock loading, high shaft runout and abrasives often associated with pulpers recycling office paper and old corrugated containers (OCC). The entire assembly is fully-split and serviceable onsite.