How to Plan for a Successful Project

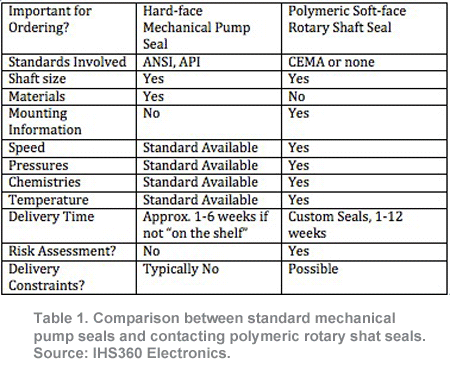

There are often misconceptions surrounding the availability of contacting, polymeric rotary shaft seals. Much of this misunderstanding comes from assumptions made by comparing contacting, polymeric rotary shaft seals to hard-faced mechanical pump seals. Pump seals are readily available as “off the shelf” items for purchase due to the progression of historic ANSI & API manufacturing standards for sizing and operational settings encompassing a wide range of pressures, speeds and liquids. Typically, pump seals are available within a 1-4 week timeframe.

There are often misconceptions surrounding the availability of contacting, polymeric rotary shaft seals. Much of this misunderstanding comes from assumptions made by comparing contacting, polymeric rotary shaft seals to hard-faced mechanical pump seals. Pump seals are readily available as “off the shelf” items for purchase due to the progression of historic ANSI & API manufacturing standards for sizing and operational settings encompassing a wide range of pressures, speeds and liquids. Typically, pump seals are available within a 1-4 week timeframe.

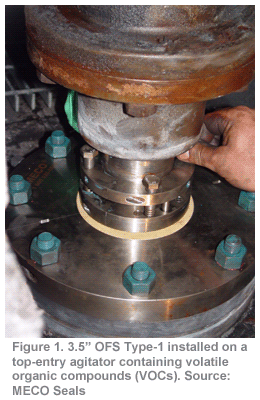

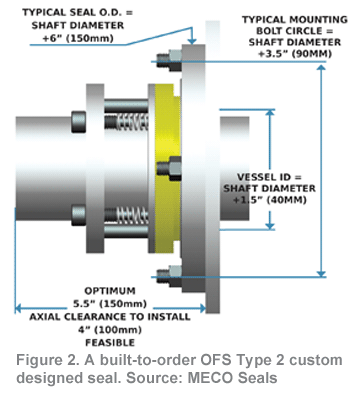

In contrast, contacting, polymeric rotary shaft seals have a shorter historic basis, are sized according to OEM specifications, designed for specific applications, and are sensitive to over loading. On new applications, often a design review is needed to match the correct seal to the application parameters. The Conveying Equipment Manufacturer’s Association (C.E.M.A), provides a loose standard for 6 common screw conveyor sizes used for material handling, however standard sizes don’t exist for other types of equipment, such as mixers, blenders, crystallizers, extruders, agitators, dryers and rotary feeders to name a few.

Due to the vast process variations from one industry to another, as well as the proprietary nature of OEM designs, contacting polymeric rotary shaft seals may take anywhere from 2-12 weeks to design and manufacture. By working closely with end-users, OEMs and/or consulting engineers, the proper contacting face seal is recommended for a customer’s design specifications. This may come as a shock to some, and our goal is to educate those making purchasing decisions so their projects can run efficiently and on time.

Critical considerations are necessary when planning projects requiring contacting, polymeric rotary shaft seals. Here we have highlighted some best practices to put in perspective why planning ahead is so important.